Diffusion Pump Oil is one of the

costliest consumables required by vacuum users. In the present day scenario of cut

throat competition, engineers are under a lot of pressure to reduce costs

without compromising on quality. Based on my experience of almost 20 years in

the vacuum line, I have compiled a list of do's and don'ts as to how one can

get maximum life from the diffusion pump oil. For the benefit of our valued

customers, the facts are given below -

1.

Topping

up at regular intervals is most important factor in getting maximum life from

Diffusion Pump Oil. Care should be taken to top up the oil in the pump in a

timely manner. In the absence of topping up, volume of oil in the Diffusion

Pump reduces, whereas heaters keep producing the same amount of heat. This

causes overheating and accelerated loss of DP oil. This further reduces the

volume of oil, which in turn causes more overheating and loss of DP oil is

further accelerated and so on.

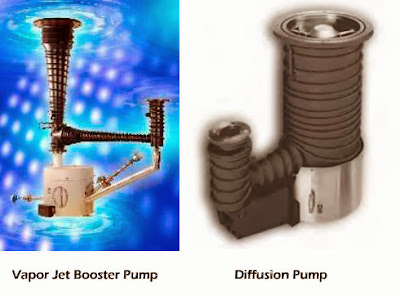

Diagram of

Diffusion Pump

2.

Keep

track of the water flow through the cooling lines. Check the inlet and outlet

water temperature as well as the flow rate. Lines can become clogged or scaled

over time. As Diffusion Pump oil vapor can only condense on coming in contact

with cold walls of DP. Any reduction in cooling causes overheating and increase

of pressure inside DP. This may result in loss of oil by back streaming.

3.

Strange

as it may sound a very low fore- pressure can also cause loss of DP oil. This

can be prevented by switching on heaters before fore pressure becomes too low.

5.

Silicone

diffusion Pump Oils have a life of about 4 times that of Hydrocarbon Diffusion

Pump Oils. Also Silicone Diffusion Pump oil does not blacken and clog the jets

of DP so Silicone DP oil works out more economical in the long run.

6. Poorly working Rotary Pump will put extra burden on diffusion pump. It must be ensured that Rotary pump is working properly to get full life from Diffusion Pump Oil.

6. Poorly working Rotary Pump will put extra burden on diffusion pump. It must be ensured that Rotary pump is working properly to get full life from Diffusion Pump Oil.

7.

Do not

expose the oil to air when it is heated. Doing so will affect the viscosity of

the oil – it thickens and vacuum reduces. To avoid air exposure valves must be

checked from time to time.

8.

To avoid

having the oil migrate into the vacuum chamber, a cold cap should be fitted at

the top of the nozzle assembly inside the diffusion pump. This cold cap

condenses the vapor in that area.

9.

A

concentric circular chevron baffle should be present at the mouth of the pump.

It allows air molecules to wander in, but traps the heavier oil vapors as they

try to escape.

11. Sometimes

back streaming of contaminants from the vacuum chamber takes place causing the

oil to form sludge. This is preventable by installing filters above the chevron

baffle of the diffusion pump.

12.

Silicone diffusion pump oil starts to decompose if it comes in contact with even trace

elements of alkali metals (e.g. hydroxides of sodium, potassium, cesium

etc.). If process requires use of these then care should be exercised to

prevent them reaching silicone DP oil.

13. In

processes like PVD, coatings requiring plasma or transparent metalizing, gas

load can cause vacuum of diffusion pump to fall below 10-1Torr. This

can result in back streaming of DP Oil or even stalling. This is preventable by

reducing the process speed or increasing the capacity of backing pumps.

Written by: Anshuman Punj.