Q.11 How to prevent back streaming of diffusion pump oil?

Diffusion pump diagram

Ans. To

prevent back streaming of Diffusion Pump oil it must be ensured that-

1. System

is "Roughed out" before Diffusion Pump is put in line.

2.

Rotary vacuum pump is maintaining a vacuum of at

least 10-2 Torr.

3.

If

process is causing release of a large amount of gas, then sometimes it

may be required to slow down the process.

4.

Cooling

water output volume and temperature must be checked. If this is not as per the

manufacturer's recommended values then descaling and increasing cooling

water circulation is required.

5.

If

problem of back streaming is frequent then increasing the capacity of backing

pump is required to solve it.

6.

Diffusion

pump must have a cryotrap or at least baffles on top to trap gasses trying to

flow out of pump into chamber.

7.

All

the valves should be checked from time to time.

8.

Strange

as it may sound, very low fore pressure can also cause back streaming.

Q.12 Why is diffusion pump water cooled?

Cooling

coils around diffusion pump

Ans. A diffusion pump has no moving parts and

therefore depends on diffusion pump oil for creation of vacuum by action of gas

diffusion.

For diffusion to occur the diffusion pump oil is

heated and vaporized using heaters. It is then released through jets at high

speed and in this way it traps air by diffusion process. Then it is cooled at

walls of diffusion pump. This liquefies the oil vapors and these vapors again

turn to liquid state. This completes the cycle and the process repeats

continuously.

Q.13 I have a Chinese diffusion pump (Not Varian) do I need to use

some different kind of diffusion pump oil?

Ans. Diffusion pumps as well as Diffusion pump oils are made as per a

standard engineering practice of interchangeability. So a good Diffusion pump

oil will be suitable for any Diffusion pump made anywhere in the world.

Just like same petrol works for cars made by Honda, Suzuki, Audi,

Toyota or any other brand.

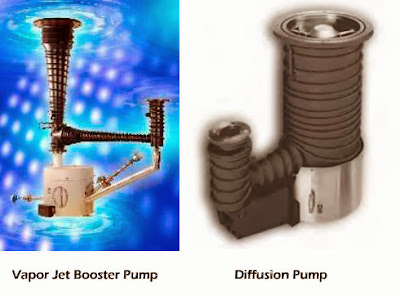

Q.14 What is the difference between Vapor Jet Booster Pump (Ejector

Pump) and Diffusion Pump?

Ans. Although vapor jet booster or ejector pump works on the same

principle as diffusion pump but there are many differences, these are given

below:--

1. The jet design of diffusion pump and vapor jet booster pump are

different. In diffusion pump oil vapors are compressed to a higher compression

ratio compared to ejector pump.

2. Because of higher compression ratio diffusion pump is capable

of producing vacuum up to 1x10-10 Torr. Where as an ejector pump

cannot produce vacuum above 1x10-5 Torr.

3. Vapor jet booster pump creates vacuum in a shorter time than

diffusion pump.

4. In an ejector pump the working fluid i.e. vapors jet booster

pump oil has lower boiling temperature compared to diffusion pump oil used in

diffusion pump.

Q.15 When Should I check the diffusion pump oil level? In hot

condition or cold condition?

Ans. Level of diffusion pump oil should always be checked when pump is

cold. In hot condition some oil will be in vapor state so correct level will

not be indicated.

Q.16 While changing diffusion pump oil should we wait till pump

cools down or is this not required?

Ans. You should always wait for diffusion pump oil to cool down to room

temperature before taking it out of diffusion pump. Diffusion pump oil when

heated is at a temperature above 200oC. Trying to take out oil at

this temperature can be very dangerous.

Q.17 What is shelf life of silicone diffusion pump oil?

SV-SIGMA

Ans. If stored properly, shelf life of Silicone diffusion pump oil is 2

years.

Q.18 Which oil is more economical to use hydrocarbon DP oil or

silicone diffusion pump oil?

Ans. Under normal circumstances silicone diffusion pump oil works out

cheaper because of its long life and no requirement of maintenance. However if

plant is very old or process involves emission of corrosive gasses, then

hydrocarbon oil may work out cheaper.

To know more about

this please click here.

Q.19 Why is it important to check level of diffusion pump oil

regularly?

Ans. In case level of diffusion pump oil reduces then thermal

equilibrium in diffusion pump is disturbed. This causes Diffusion Pump Oil to

overheat, which results in oil loss, loss of vacuum and damage to diffusion

pump in extreme cases. It is therefore important to check the level of

diffusion pump oil regularly and top it up if required.

For more tips click here.

Q.20 Can I reuse diffusion pump oil?

Used diffusion pump oil

Ans. No, diffusion pump oil cannot be reused. This is

because while creating vacuum diffusion pump oil is subjected to very high

temperature and extreme vacuum. This destroys the molecular structure of oil

which cannot be corrected by filtration or distillation.

About this read more here.

Written by: Anshuman Punj.

No comments:

Post a Comment