In the present time of intense competition, it is natural that engineers are trying hard to optimize the use of every resource to reduce costs. In Metalizing, Evaporation Boats undoubtedly contribute most in variable cost. It is therefore important that maximum life is derived from Evaporation Boats without affecting the quality of Metalizing.

Based on my knowledge of Engineering,

experience of nearly 20 years in vacuum line and interaction with actual users,

I have compiled a list of measures which if implemented can ‘enhance’ the life

of Evaporation boats by about 25% so that you get your money’s worth out of it.

These have been

summarized as under -

1)

Initial

heating of the new boats also called “break in” must always be slow to get

proper life from Boats.

Reason? New boats will always have some absorbed moisture. If the boat is

heated quickly in this condition, the moisture, converted into steam having

much higher volume will have little time to escape and can cause cracks because

of high pressure build up.

2)

At the end of the

cycle it must be ensured that all the Aluminum or any other metal being metalized

has evaporated completely before heating is switched off. Otherwise residual metal will seep

into the pores of boats; now differential cooling rates of boat and metal will

crack the boat.

3)

Care must be exercised that before the

vacuum is broken, boats must have cooled down. This is because sudden contact with cold air can

cause boat breakage. About 5 minutes is enough for boats to cool down.

4)

Worn out copper clamps also are a big

reason for boats not performing to their full capacity. Non uniform wear of clamp causes

sparking between clamp and boat; this overheats and cracks the boat.

5)

A good quality graphite foil is very

important factor in enhancing the life of Boat. To save money, sometimes Metalizers use poor quality

plumbing grade graphite foil. This foil contains many impurities and binders

and offers resistance to the flow of current. This causes the ends of boat to overheat

and break. Supervac supplies 100% pure graphite foil free of binders. This is

made with the patented process of Exfoliation. This foil gives you the

following outstanding benefits –

A)

Offers no resistance to the flow of

current.

B)

Saves costly power.

C)

Enhances the life of Boats.

6)

There is one more major factor inter

linking the life of evaporation boat with graphite foil. Good quality graphite foil

has good compressibility.

This allows a proper electrical contact in boats and clamp before heating

begins and expansion of boats in heated condition. Poor quality graphite foil

on the other hand will not allow expansion of boats in heated condition putting

additional stress and subsequent breakage of boats.

7)

Aluminum of purity 99% or more is required

to avoid premature cracking. Impure aluminum will have impurities which will have different boiling

temperatures; this will lead to an unstable pool of metal in boat cavity. This

in turn results in non uniform heating of Evaporation Boat leading to thermal

stress and breakage.

8)

Age of aluminum wire also affects boat

life. With age, aluminum

oxidizes and Aluminum oxide thus formed causes spitting and excessive heating

of Boats. Freshly made or “cleaned” wire works best.

9) Hardness

of Aluminum should be maintained in proper range if required by tempering as a

very hard wire is likely to puncture the boats.

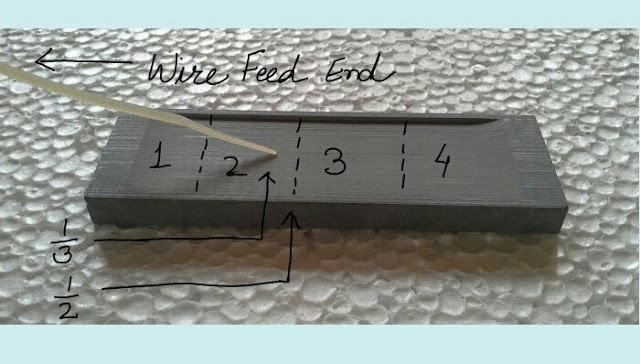

10) Aluminum wire should be fed in such a way that it meets boat in the center widthwise and in between 1/3 to ½ lengthwise. This ensures proper pool formation and increases the life of boats. (I have written a blog post entirely on this topic in the past. You can read it here.)

11) Feed of aluminum wire must be regulated to

ensure that some aluminum is always available as molten “pool” on the surface

of Boat. This makes sure

that boat is uniformly heated and increases the life of boat.

12) Power to boat must be so regulated that

aluminum melts just before touching the boat , otherwise it will cause an indentation in boat cavity,

hastening the failure of boat.

13) It

has been observed that Boats made of Titanium Diboride and Boron

Nitride (also called 2 components or dimet) work out to be more economical than boats where Aluminum nitride is

also used in addition to the 2 ceramic powders mentioned above to reduce the

cost. Three component boats, though cheaper in cost, have a markedly shorter

life.

14)

Experience shows that normal rectangular

boats with cavity work out cheaper then Triangular or elliptical boats or boats

without cavity or laser grooves on surface.

15)

Good quality boats, manufactured by reputed

companies like Supervac, having density of the order of 98% of theoretical

density have very low porosity. This reduces aluminum seepage in boats and enhances life of boat. These

boats work out much more economical than those supplied by phony “importers”/

unknown companies having no quality standards.

16) Contrary to popular myth, using boats with

initial resistivity higher then recommended by manufacturer does not give more

life. In fact this

wastes power, causes overheating and premature cracking of boats.

17) Experience proves that spring loaded end support

for boats works best for optimizing the life of boats as it provides a proper contact and

allows expansion of boats on heating.

18) Level of vacuum in system is also very

important for getting proper life from boat. Working at vacuum above 1x 10-4 Torr is

detrimental to the health of Boats as they get oxidized and damaged.( For

getting high level of vacuum in shortest possible time Supervac Sigma+™ Diffusion Pump oil and Supervac SV-77™ Rotary Vacuum Pump Oil can be used.)

Points mentioned above are quite easy to implement and best of all do not cost an extra rupee. This however can result in a saving of about Rs. 9, 00,000/- per year per metallizer (a typical metallizer uses about 300 boats per month, costing about Rs.1, 000 per boat. Saving is 300 x12 x1000 x25% = Rs.9, 00,000/-). This is not all; implementation of these actions will also lead to better metalizing quality, better maintained plant and saving of costly power also.

Written by: Anshuman Punj.